Have you ever considered upgrading your floors with epoxy but didn’t know where to start? This article will explore everything you need to know about epoxy flooring, including the different types available and why it’s a popular choice for many homeowners. We’ll also walk you through the steps to create a stunning marble effect using epoxy, as well as provide tips on how to maintain your epoxy floors for long-lasting beauty. So, let’s dive in and discover the world of epoxy flooring!

What Is Epoxy Flooring?

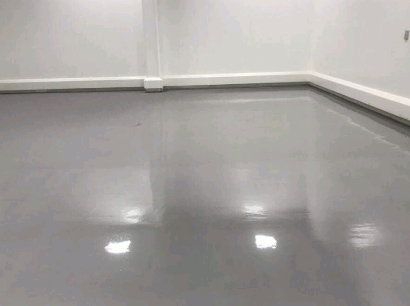

Epoxy flooring refers to a specialized surface created by applying multiple layers of epoxy resin over an existing floor to achieve a glossy finish and enhance the aesthetics of the space.

This process involves mixing a resin with a hardening agent, creating a chemical bond that is highly durable and resistant to stains, impacts, and chemicals. The application of epoxy flooring not only improves the visual appeal of the floor but also adds a protective layer that can extend the lifespan of the underlying surface. The glossy finish provided by epoxy coating can transform dull concrete floors into sleek, modern spaces, making it a popular choice in commercial and industrial settings where both functionality and style are crucial.

Why Choose Epoxy Flooring?

Choosing epoxy flooring offers a durable, cost-effective solution that transforms ordinary floors into unique, eye-catching surfaces with minimal maintenance requirements.

The durability of epoxy flooring is remarkable, as it can withstand heavy foot traffic, impacts, and chemical spills without showing signs of wear and tear. This longevity not only reduces the need for frequent repairs but also ensures that the flooring maintains its pristine appearance for years to come.

In terms of cost-efficiency, epoxy flooring is a wise investment due to its long lifespan and low maintenance needs, saving both time and money in the long run. The transformative properties of epoxy allow for endless design possibilities, from creating a sleek, modern look to replicating the appearance of high-end materials like marble or granite.

Uncover more: Can Epoxy Flooring Be Used In Bathrooms

What Are The Different Types Of Epoxy Flooring?

There are various types of epoxy flooring options available, including self-leveling, mortar, flake, metallic, and quartz-filled floors, each offering distinct characteristics and applications.

- Self-leveling epoxy floors are known for their smooth and seamless finish, making them ideal for areas requiring a level surface like garages and warehouses.

- Mortar epoxy flooring is incredibly durable and resistant to heavy impacts, popular in industrial settings where strength is crucial.

- Flake epoxy floors provide a decorative touch with a multitude of color and pattern options, suitable for commercial spaces.

- Metallic epoxy flooring creates a glossy, high-end look with unique marbled effects, commonly used in retail and residential settings.

- Quartz-filled epoxy floors offer exceptional durability and slip resistance, perfect for areas with high foot traffic such as hospitals and restaurants.

Self-Leveling Epoxy Floors

Self-leveling epoxy floors are a popular choice known for their smooth finish, achieved through advanced techniques that create a professional, glossy appearance.

These floors are applied in a liquid form that spreads evenly across the surface, automatically filling in imperfections and creating a seamless finish. This process involves careful mixing of the epoxy resin and hardener to ensure proper consistency and self-leveling properties. Once poured, the epoxy mixture naturally seeks its own level, resulting in a surface that is free of bumps or unevenness. The final result is a high-gloss, reflective finish that not only looks luxurious but also enhances the overall aesthetics of any space.

Epoxy Mortar Floors

Epoxy mortar floors are renowned for their durability and strength, requiring precise mixing and pouring techniques to achieve a sturdy surface that is resistant to staining.

Utilizing the right tools, such as a mixing paddle attachment for a drill and a notched trowel for proper spreading, is essential in the process.

The mixture must be carefully combined to ensure maximum strength and adhesion. The pour should be executed smoothly and evenly to prevent any imperfections or weak spots in the flooring.

The stain-resistant properties of epoxy mortar floors make them ideal for high-traffic areas or spaces prone to spills, offering easy maintenance and longevity in various settings.

Epoxy Flake Floors

Epoxy flake floors incorporate decorative pigments and flakes, spread over the epoxy resin before sealing and polishing to create a vibrant, textured surface.

These decorative pigments and flakes come in a myriad of colors and sizes, allowing for endless design possibilities. During the spreading process, skilled professionals evenly disperse the flakes, ensuring a uniform distribution for a seamless finish. Sealing the floor not only enhances the visual appeal but also provides durability and resistance to stains and abrasions. Polishing the surface adds a glossy sheen, highlighting the unique texture and depth created by the pigments and flakes.

Metallic Epoxy Floors

Metallic epoxy floors feature captivating swirls and veins created through the unique application of metallic powders and specialized swirl techniques, resulting in a stunning, high-gloss finish.

The magic of metallic powders lies in their ability to create a sense of movement and dimension on the floor, almost like a piece of abstract art underfoot. The specialized swirl techniques used by skilled artisans result in a marbled effect that is both luxurious and eye-catching. The high-gloss finish enhances the depth of the swirls, reflecting light and creating a sense of space and sophistication in any room. These floors evoke a sense of elegance and modernity, transforming a space into a work of art.

Quartz-Filled Epoxy Floors

Quartz-filled epoxy floors combine the beauty of natural stone with the durability of epoxy, featuring distinctive veins and variegated patterns enhanced by a clear coat for added protection and aesthetic appeal.

This flooring option provides a seamless blend of elegance and functionality, making it a popular choice for both residential and commercial spaces. The unique character of quartz-filled epoxy floors lies in the organic veins that meander through the surface, creating captivating visual interest. These variegated patterns add depth and dimension to any room, infusing a touch of luxury.

The application of a clear coat not only safeguards the floor against wear and tear but also intensifies the richness of colors and enhances the overall aesthetic. With its combination of natural beauty and durability, quartz-filled epoxy flooring stands out as a versatile and stylish flooring solution.

How To Create A Marble Effect With Epoxy Flooring?

Transforming floors with a stunning marble effect using epoxy involves a step-by-step process that includes marbleizing techniques, veining application, and proper sealing for long-lasting beauty.

- To start the DIY marble effect with epoxy flooring, begin by preparing the space thoroughly and clearing it of any debris.

- Mix the epoxy resin with the desired colors to achieve the marble effect you desire.

- When applying the mixture, utilize various marbleizing techniques such as feathering, blending, and swirling to mimic the natural patterns of marble.

Next, carefully add veining details by using a small paintbrush or tool to create the intricate veins characteristic of marble. Once the design is in place, seal the floor with a high-quality epoxy sealant to protect the finish and ensure durability over time.

Prepare The Floor

Preparing the floor is the initial step in the epoxy flooring process, involving surface assessment, potential resurfacing, and ensuring a waterproof foundation for long-lasting results.

- Surface evaluation is crucial to identify any imperfections or existing coatings that may impact the adhesion of the epoxy. Conducting a thorough inspection allows for proper preparation, which can involve grinding or shot blasting to create a clean and porous surface for the epoxy to bond effectively.

- Considering potential resurfacing options such as repair of cracks or uneven areas before applying the epoxy is essential to achieve a smooth and uniform finish.

- A waterproof base is paramount to prevent moisture issues that could compromise the durability and longevity of the epoxy flooring.

Apply A Base Coat

Applying a base coat of epoxy resin allows for customized color options and ensures a scratch-resistant foundation for the subsequent layers of epoxy in creating the marble effect.

This initial layer of epoxy acts as a protective barrier, preventing any imperfections or scratches from appearing on the surface. The customization aspect is crucial as it gives you the flexibility to choose the exact shade and design that aligns with your aesthetic preferences. By incorporating scratch-resistant properties into the base coat, the overall durability of the epoxy flooring is heightened, guaranteeing a long-lasting and visually appealing finish that mimics the luxurious look of marble without the high maintenance.

Mix And Apply The Epoxy Resin

Mixing and applying the epoxy resin involves incorporating metallic powders and utilizing skilled techniques to achieve a timeless, marbled appearance on the floor.

- By adding metallic powders to the resin mixture, the unique effect can be enhanced further.

- To achieve the marbled finish, the resin must be poured in a controlled manner, allowing for swirls and patterns to naturally form.

- Understanding the right consistency of the resin is crucial for successful pouring.

With a steady hand and attention to detail, skilled artisans can manipulate the resin to create intricate designs. The process requires patience and precision to ensure a high-quality result that mimics the luxurious look of natural marble.

Create The Marble Effect

Crafting the marble effect involves artistic swirls and creative designs with epoxy to achieve a visually appealing floor, enhanced by UV protection for long-term color retention.

- One popular technique for achieving the marble effect is the ‘swirl method’, where different colored epoxy resins are blended in a swirling motion to mimic the natural patterns found in marble. This method allows for endless creative possibilities, as each swirl can be unique and customized to suit the desired aesthetic.

- Incorporating shimmering metallic pigments or glitter can also add a touch of elegance and sophistication to the design, elevating the overall look of the floor. Ensuring adequate UV protection is crucial to prevent discoloration and maintain the vibrancy of the colors over time.

Seal The Floor

Sealing the floor with a clear coat ensures waterproofing, and durability, and provides maintenance tips for preserving the beauty and longevity of the epoxy marble effect.

This sealing process is crucial for protecting the floor against moisture, stains, and wear and tear. Applying a clear coat not only enhances the glossy finish of the epoxy but also acts as a barrier to keep water out. To maintain the marble effect’s allure, it is recommended to regularly clean the surface with a mild detergent and avoid using harsh chemicals that may damage the clear coat. Periodic reapplication of the clear coat can help extend the floor’s lifespan and retain its original charm.

What Are The Tips For Maintaining Epoxy Floors?

Maintaining epoxy floors involves regular cleaning, the use of protective mats, timely repairs, and reapplying a topcoat as needed to ensure the longevity and aesthetics of the flooring.

Regular cleaning is crucial for removing dirt and debris that can scratch or damage the epoxy surface. Protective mats offer additional safeguarding against heavy foot traffic or potential spills, extending the life of your flooring.

Timely repairs prevent small issues from escalating into more significant problems that could compromise the integrity of the floor. Reapplying a topcoat not only enhances the appearance but also acts as a protective barrier against wear and tear, maintaining the floor’s durability and visual appeal.

Regular Cleaning

Regular cleaning is essential for maintaining the luster and durability of epoxy floors, requiring a skilled technique to ensure the longevity of the finish.

Without proper cleaning, dust and debris can accumulate, causing abrasions that dull the surface over time. A skilled maintenance routine not only keeps the epoxy floors looking fresh but also extends their lifespan. By using appropriate cleaning agents and techniques, you can effectively remove stains and prevent scratches that could compromise the durability of the flooring.

Consistent care and attention to detail are vital to preserving the seamless beauty and resilience of epoxy floors in both residential and commercial settings.

Avoid Harsh Chemicals

Avoiding harsh chemicals is crucial to maintaining stain resistance and enhancing the aesthetics of epoxy floors, preserving their visual appeal and longevity.

Harsh chemicals can compromise the protective coating of epoxy floors, leaving them vulnerable to stains and discoloration. By using gentle cleaning agents and avoiding harsh solvents, you can ensure that your floors retain their glossy finish and vibrant colors. This not only improves the overall aesthetic of the space but also prolongs the durability of the flooring.

Regular maintenance with appropriate cleaning products will help preserve the sleek appearance of the epoxy floors, making them a long-lasting and stylish addition to any environment.

Use Protective Mats

Utilizing protective mats helps maintain the seamless finish of epoxy floors, offering a customized look and preserving the overall aesthetics of the space.

These mats act as a barrier against scratches, dents, and spills, ensuring long-lasting durability for your epoxy floors. They provide a cushioned surface that reduces fatigue when standing or walking on the floor for extended periods. The option to customize these mats with various colors, patterns, and sizes allows you to create a cohesive design scheme that complements the space. By integrating protective mats into your flooring design, you not only enhance the aesthetic appeal but also extend the lifespan of your epoxy flooring investment.

Repair Any Damage

Timely repairs are essential for maintaining pattern consistency on epoxy floors, enhancing the property value and visual appeal of the space.

Regular upkeep not only ensures that the intricate designs and patterns on your epoxy floors remain consistent, but it also plays a significant role in boosting the overall value of your property. By addressing any damages promptly, you not only prevent further deterioration but also retain the aesthetic appeal of the flooring. Consistency in maintenance is key to preserving the beauty of the space and ensuring that potential buyers or visitors are greeted with a visually appealing environment.

Reapply A Topcoat As Needed

Reapplying a topcoat as needed ensures the scratch-resistant properties of epoxy floors and allows for a designer touch to enhance the aesthetic appeal of the flooring.

Over time, the daily wear and tear on epoxy floors can compromise their durability and aesthetics. By incorporating periodic topcoat reapplications into your maintenance routine, you not only maintain the scratch resistance of the flooring but also have the opportunity to introduce new design elements. Topcoats act as a protective layer, shielding the floor from scratches, stains, and UV damage, while also offering a platform for adding unique patterns, colors, and textures to uplift the overall look of the space.