Roof coating is a critical yet frequently underestimated component of maintaining a building’s structural integrity and operational efficiency, particularly when considering the eco-friendly benefits it offers. This article examines the concept of roof coating, detailing the various types available—including acrylic, silicone, polyurethane, and bitumen—and the numerous advantages they provide, ranging from waterproofing to improved energy efficiency. Additionally, it addresses common inquiries regarding the waterproofing capabilities of roof coatings and the factors that influence their effectiveness, such as weather conditions and the quality of polymers used. Understanding how the appropriate roof coating can utilize high-quality liquid coating to prolong the lifespan of a roof and contribute to cost savings over time is essential for informed decision-making.

What is Roof Coating?

Roof coating is a specialized protective layer applied to the roof surface, significantly enhancing its waterproofing capabilities, durability, and energy efficiency, making it ideal for both flat roofs and low-slope roofs. This application creates a seamless waterproof barrier that safeguards against various weather conditions, including ultraviolet damage and water absorption, thereby extending the lifespan of roofing systems.

Roof coatings, such as RD Coatings and RD-Elastodeck, can be environmentally friendly and incorporate advanced liquid-applied technology to provide exceptional properties and low maintenance requirements. Consequently, they represent an optimal choice for both building managers and homeowners.

Take a look: Can You Paint A Roof

What Types of Roof Coating Are There?

There are various types of roof coatings designed to accommodate different roofing substrates and project requirements, each providing distinct benefits and applications.

Among the most widely used are:

- Acrylic coatings, recognized for their high solar reflectance;

- Silicone coatings, which excel in waterproofing capabilities and UV protection, preventing ponding water damage;

- Polyurethane coatings, noted for their exceptional durability and chemical resistance;

- Bitumen coatings are celebrated for their anti-corrosion properties.

These single-component, liquid-applied systems are applicable in both commercial roofing projects and residential renovations, ensuring the establishment of a dependable waterproof barrier that offers high solar reflectance and energy efficiency.

Acrylic Roof Coating

Acrylic roof coating represents a water-based technology that offers superior water resistance and energy efficiency, making it an increasingly popular option for flat and low-slope roofs. This innovative solution not only extends the lifespan of roofing systems but also enhances overall building performance, allowing property owners to realize long-term benefits while minimizing repair expenses and cooling costs.

When evaluating the application of acrylic roof coatings, several key considerations are paramount:

- Reflective Properties: These coatings significantly diminish heat absorption, resulting in lower indoor temperatures and reduced dependence on air conditioning systems during warmer months.

- Energy Efficiency: Enhanced energy efficiency leads to decreased utility costs, positioning these coatings as a prudent investment for both residential and commercial properties.

- Low VOC Emissions: With minimal volatile organic compound (VOC) emissions, these coatings contribute to improved indoor air quality while adhering to environmental regulations and promoting sustainability.

Application techniques may vary; however, they typically involve thorough surface preparation, the application of multiple coats, and regular inspections to ensure long-term durability.

Maintenance includes periodic cleaning and reapplication, ensuring that the advantages of acrylic roof coatings are sustained over many years. The effective use of these coatings in both residential and commercial projects not only enhances aesthetic appeal but also promotes sustainability in roofing practices.

Silicone Roof Coating

Silicone roof coating is an advanced waterproofing solution recognized for its exceptional performance in UV protection and resistance to ponding water.

This innovative product offers a seamless application that creates a durable barrier, effectively preventing water infiltration and maintaining the structural integrity of roofing systems, which is crucial for both residential and commercial roofing. Its reflective properties enhance energy efficiency by reducing heat absorption, potentially leading to lower cooling costs.

For optimal application, contractors recommend executing the process in dry conditions with temperatures exceeding 50°F. Regular maintenance should include periodic inspections to ensure proper adhesion and to identify any signs of wear.

Property owners can derive significant benefits from this long-lasting solution, which provides a cost-effective approach to enhancing the lifespan and performance of roofs.

Polyurethane Roof Coating

Polyurethane roof coating is widely recognized for its durability and exceptional chemical resistance, offering a robust protective layer for roofing systems. This outstanding material is engineered to endure the demands of both commercial and residential environments. It exhibits high tensile strength, which significantly enhances its ability to resist physical stresses such as wind uplift and foot traffic. Both homeowners and business owners can leverage its versatility, as it readily adapts to a variety of weather conditions, providing surface protection against harsh UV rays, heavy rainfall, and extreme temperatures.

Potential applications include:

- Flat roofs in commercial buildings

- Residential rooftops

- Industrial applications where chemical exposure is a concern

The overall advantages of polyurethane roof coating encompass prolonged roof life, improved energy efficiency, and reduced maintenance costs, making it an appealing choice for individuals seeking to invest in durable roofing solutions and repairs.

What are the Benefits of Roof Coating?

Roof coatings provide numerous advantages, including exceptional waterproofing capabilities, improved energy efficiency, and an extended lifespan for roofs, thereby representing a worthwhile investment for property owners.

The application of a high-quality liquid coating enables building managers to substantially decrease energy consumption and cooling expenses, while simultaneously preventing water damage and reducing long-term maintenance demands through reliable waterproof membranes.

These coatings serve to protect the roof and also enhance the aesthetic appeal and durability against adverse weather conditions, fulfilling project requirements with elastomeric coatings.

Waterproofing

Waterproofing stands as one of the primary advantages of roof coatings, as they establish a dependable waterproof barrier that safeguards against water damage and moisture management issues.

The various types of roof coatings, including acrylic, silicone, polyurethane, and asphalt-based options, each play a distinctive role in enhancing this protective layer. By applying these coatings, property owners can effectively reduce the risks associated with leaks and water absorption, thereby significantly improving the lifespan and performance of their roofing systems.

For example, silicone coatings provide exceptional resistance to moisture while reflecting sunlight, which not only helps to keep the roof cool but also extends the longevity of the coating. Conversely, acrylic coatings are well-regarded for their ease of application and excellent adhesion properties, resulting in a seamless and durable seal.

- Leaking Prevention: Proper coatings serve as a barrier against water infiltration.

- Enhanced Longevity: Regular maintenance with coatings can significantly prolong roof life.

- Energy Efficiency: Reflective coatings can lead to reduced energy costs by enhancing insulation.

Investing in suitable roof coatings extends beyond mere aesthetics; it is essential for preserving the overall integrity of the building.

Energy Efficiency

Energy efficiency is significantly enhanced by roof coatings that possess reflective properties, which can substantially decrease cooling costs in both commercial and residential buildings. These specialized coatings are engineered to reflect a high percentage of solar energy, thereby minimizing heat absorption and maintaining more stable indoor temperatures during warmer months.

Such advancements in roofing technology have proven to be exceptionally advantageous. Research indicates that structures equipped with high solar reflectance coatings can achieve energy savings of up to 20% on cooling costs. For example, a white reflective roof can reduce roofing surface temperatures by approximately 30 to 50 degrees Fahrenheit compared to traditional dark roofs.

- Research from the Cool Roofs program suggests that cities can lower their overall energy demand by 10 to 20% through the adoption of reflective surfaces.

- This not only mitigates heat island effects but also enhances overall comfort levels in urban environments.

By implementing such technologies, building owners can realize savings on utility bills while also making a positive contribution to the environment by reducing greenhouse gas emissions associated with excessive energy consumption.

Protection Against UV Rays

Roof coatings, including innovative solutions such as RD coatings and RD-Elastodeck, serve a critical role in safeguarding roofing systems from the detrimental effects of harmful UV rays, which can degrade roofing substrates and significantly shorten their lifespan.

These coatings function as an effective barrier, reflecting sunlight and minimizing heat absorption, thereby alleviating the damaging consequences associated with prolonged UV exposure. In the absence of adequate protection, roofing materials such as asphalt, metal, and single-ply membranes are susceptible to accelerated deterioration, which can manifest in problems such as cracking, bubbling, and granule loss.

The degree of UV damage varies among different types of coatings, which are evaluated by organizations like the Cool Roof Rating Council:

- Asphalt-based coatings: While initially effective, these may deteriorate more rapidly under intense sunlight exposure.

- Elastomeric coatings: These coatings offer superior flexibility, accommodating expansion and contraction while providing excellent UV resistance.

- Acrylic coatings: Recognized for their cost-effectiveness and UV reflectivity, acrylic coatings are a popular option; however, they may necessitate more frequent reapplication.

In summary, ensuring adequate UV protection for roofing not only maintains the structural integrity of the materials but also enhances energy efficiency by lowering rooftop temperatures.

Extended Roof Lifespan

An extended roof lifespan is a notable advantage of applying roof coatings, like RD Coatings and Unicoat Industrial Roofing, which significantly enhance the overall durability of roofing systems and reduce the necessity for frequent repairs.

The application of roof coatings not only contributes to the aesthetic appeal of a building but also provides a robust layer of protection against harsh environmental conditions. These coatings function as a shield, markedly improving resilience to extreme weather factors such as ultraviolet (UV) rays, heavy rainfall, and temperature fluctuations. Their capacity to mitigate the effects of wear and tear can result in substantial cost savings over time.

Various types of roof coatings, including acrylic, silicone, and polyurethane, each offer distinct benefits:

- Acrylic coatings provide excellent UV protection and are water-based, making them easy to apply and environmentally friendly.

- Silicone coatings excel in water resistance and are particularly suitable for regions prone to rainfall.

- Polyurethane coatings deliver superior durability and resistance to foot traffic, rendering them ideal for commercial roofs.

By selecting the appropriate coating, property owners can ensure that their roofs remain in optimal condition for years to come.

Cost Savings

Cost savings are frequently achieved through the implementation of roof coatings, as these coatings reduce maintenance requirements and enhance energy efficiency, providing significant long-term benefits to property owners.

By investing in roof coatings, property owners can effectively extend the lifespan of their roofing systems, thereby decreasing the need for frequent repairs or replacements. This increased longevity results in reduced long-term maintenance costs, which can be a substantial advantage for both residential and commercial properties.

For example, a retail space in Florida that utilized a reflective roof coating reported a 15% reduction in energy bills and an increased lifespan of the roofing material by at least 10 years following its installation. Similarly, a case study involving an industrial warehouse demonstrated a return on investment of 30% within five years due to lowered operational costs.

These examples clearly underscore the financial benefits associated with roof coatings, emphasizing their role as a cost-effective solution for maintaining optimal property conditions.

Is Roof Coating Waterproof?

Roof coatings are specifically engineered to be waterproof, establishing a robust waterproof barrier that effectively addresses moisture management issues and prevents water damage.

These coatings achieve their notable impermeability through advanced technologies, including liquid-applied systems that conform precisely to the roof’s surface. This application method ensures complete adherence, thereby minimizing potential weak points where leaks may occur. A comparison of various coating types reveals significant differences in waterproof performance.

- Polyurethane coatings provide exceptional resistance to water and UV degradation, making them particularly suitable for flat roofs.

- Acrylic coatings are recognized for their flexibility and ease of application, delivering a durable waterproof layer; however, they may necessitate more frequent maintenance.

- Silicone coatings are distinguished by their superior water resistance and longevity, particularly in environments that are susceptible to ponding water.

By selecting the appropriate type of coating, one can substantially enhance the lifespan and durability of the roofing system.

How Does Roof Coating Work?

Roof coating involves the application of a specialized liquid formulation that establishes a protective waterproof barrier on the roof surface, utilizing polymers to enhance durability. This innovative solution is designed not only to extend the lifespan of the roof but also to improve its energy efficiency by reflecting sunlight, thereby reducing heat absorption.

To achieve optimal results, it is essential to prepare the roof surface adequately. This process entails a thorough cleaning of the roof to eliminate any debris, dirt, or existing coatings that may impede adhesion. A comprehensive inspection of the surface for cracks or damage is also necessary, and any identified issues should be repaired properly prior to proceeding with the application. Once the surface is adequately prepared, the application process can commence.

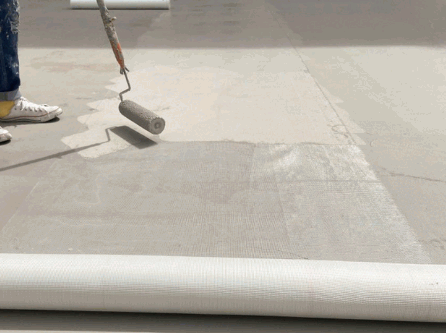

- Application Techniques: It is common practice to use a roller or a sprayer for the application. The coating should be applied evenly to ensure full coverage while avoiding pooling.

- Curing Time: After the application, it is imperative to allow the coating to cure completely, which may take several hours to a few days depending on environmental conditions.

Adhering to the manufacturer’s application instructions is crucial to ensure a seamless application and optimal performance.

What Factors Affect the Waterproofing Ability of Roof Coating?

Numerous factors influence the waterproofing efficacy of roof coatings. These include the method of application, the quality of the materials utilized, the condition of the roof surface, and the prevailing weather conditions at the time of application, especially in climates like Lamesa, Texas, known for extreme temperatures.

Application Method

The application method is essential for ensuring the effectiveness of roof coatings, as improper techniques can result in gaps within the waterproof barrier.

Selecting the appropriate approach for applying these coatings can significantly affect their longevity and performance. Among the various methods, spraying and rolling are two widely recognized options, each offering distinct advantages. Professional installers frequently recommend spraying for larger areas, as it facilitates a rapid and uniform application, thereby minimizing the risk of inconsistencies. Conversely, rolling may be more appropriate for smaller or intricate sections where precision is of utmost importance.

Common mistakes in the application process include inadequate surface preparation, which can impede adhesion, and applying coatings under unfavorable weather conditions, such as high humidity or extreme temperatures. Additionally, hastening through the application process often leads to insufficient coverage, which can compromise the integrity of the barrier.

Therefore, engaging skilled professionals who are well-versed in these techniques and aware of common oversights can result in a flawless and durable application.

Quality of Products Used

The quality of products utilized in roof coating significantly influences its performance, with high-quality materials providing superior waterproofing and energy efficiency. These factors are essential considerations for homeowners who seek to protect their investments and enhance the longevity of their properties.

Selecting the appropriate roof coating product can have a considerable impact on a building’s overall sustainability and functionality. Consumers should prioritize several key features:

- Durability: It is crucial to choose products capable of withstanding harsh weather conditions over time, as this helps prevent costly repairs.

- Energy Efficiency: Opting for coatings that reflect solar energy can assist in reducing cooling costs.

- VOC Emissions: Selecting low or zero VOC options contributes to improved indoor air quality.

Reputable brands such as GAF, Henry, and Liquid Roof, and pioneers in the field like Holcim Building Envelope and Gaco offer excellent options that adhere to these criteria, ensuring both protection and performance for various roofing requirements.

Condition of Roof Surface

The condition of the roof surface is a critical factor that influences the waterproofing capabilities of roof coatings, as proper surface preparation is essential for ensuring optimal adhesion.

Before the application of any coating, including specialized RD coatings or roof paint, it is imperative that the roof undergoes thorough cleaning to eliminate debris, dirt, and any existing contaminants that may obstruct the application process. This ensures that the surface is not only clean but also free from oils and residues that could impair bonding.

Furthermore, inspecting the roof for any damage is essential. It is necessary to repair any cracks or holes to prevent water intrusion, and existing seams should be adequately sealed, using advanced products like RD-Elastodeck for superior results.

By taking these necessary steps, one can enhance the effectiveness of the coating and prolong the lifespan of the roof, ultimately safeguarding the building against potential leaks and moisture-related issues, while also providing UV protection and improving energy transfers to reduce cooling costs.

Weather Conditions

Weather conditions during the application of roof coatings can significantly influence their performance, as extreme temperatures or moisture levels may hinder proper curing and adhesion. Utilizing waterborne acrylic coatings like those from RD Coatings can help manage these challenges. A thorough understanding of the various environmental factors involved can facilitate a smoother application process and result in a more durable outcome.

- In terms of temperature, most roof coatings, including those recognized by the Cool Roof Rating Council, exhibit optimal performance in moderate weather, specifically within the range of 50°F to 85°F.

- Elevated humidity levels can also impact drying times; coatings may require extended periods to cure, increasing the likelihood of dirt or debris settling on the surface.

- Additionally, precipitation, particularly rainfall, can disrupt an ongoing application, rendering the coating ineffective if applied during or immediately preceding wet conditions.

To maximize effectiveness, meticulous planning is essential. It is advisable to target clear, dry days, particularly in the spring or fall, for the application of roof coatings. This strategic timing minimizes the risk of weather-related complications and ensures a long-lasting finish.

How Can You Ensure the Waterproofing of Roof Coating?

Ensuring the effectiveness of roof coatings in providing waterproofing requires a comprehensive approach. This includes meticulous surface preparation, precise application, and consistent maintenance to preserve the integrity of the waterproof barrier. Selecting high-quality materials from suppliers like the Holcim Building Envelope can significantly enhance waterproofing efficacy.

Proper Surface Preparation

Proper surface preparation is critical for the successful application of roof coatings. This process involves comprehensive cleaning, necessary repairs, and the removal of debris to establish a strong bond. For resilient roofs, consider materials compatible with EPDM or PVC surfaces.

To commence, it is imperative that the roof surface is devoid of any loose materials or contaminants that could hinder the adhesion of the coating. This includes the following steps:

- Removing debris: Clear away leaves, branches, and dust to establish a clean working environment.

- Cleaning the surface: Utilize a pressure washer or a sturdy broom along with water to eliminate dirt, algae, and mildew.

- Inspecting for damage: Conduct a thorough inspection for cracked or loose shingles that may require replacement.

- Applying repairs: Replace or patch any damaged areas with suitable materials to ensure a smooth and consistent surface.

Each of these steps plays a significant role in ensuring that the coating adheres effectively, thereby providing long-lasting protection and enhancing the overall durability of the roof.

Thorough Application

A comprehensive application of roof coatings is essential for creating a seamless barrier that effectively establishes waterproofing and enhances the roof’s overall performance.

To achieve optimal results, it is imperative to adhere strictly to application instructions. This includes a thorough understanding of the environmental conditions that are conducive to application, as well as the necessary preparation methods. Using products like Terra-Lok Triumph from Gaco can provide additional benefits.

Employing recommended techniques such as proper surface cleaning and priming can significantly impact the adhesion and longevity of the coating. The role of professional installers in this process is critical; their expertise ensures that roof coatings are applied uniformly and effectively, thereby minimizing the risk of errors that could result in costly repairs.

Experienced professionals possess access to specialized tools that enhance both the efficiency and quality of the work, ensuring that your roof receives the comprehensive protection it requires.

Regular Maintenance

Regular maintenance is essential for preserving the waterproofing capabilities of roof coatings. This process involves routine inspections and timely repairs to address any issues that may arise. Monitoring VOC emissions and adjusting maintenance strategies accordingly can further preserve the roof’s integrity.

To ensure long-lasting performance, property owners should prioritize maintenance, as it not only enhances the integrity of the waterproof barrier but also extends the lifespan of the coating. Scheduled inspections can help identify potential problems, such as cracks, blisters, or peeling, which often go unnoticed until they escalate into more significant issues.

During these assessments, it is important to clear areas of accumulated debris to prevent moisture collection. Repairs should be conducted promptly and may include:

- Sealing gaps and cracks

- Reapplying the waterproof membrane

- Repairing any damaged flashing

By adopting a proactive maintenance approach, property owners can effectively safeguard their investments and minimize the risk of costly repairs in the future.